CAD Designing Manufacturers in Bangalore

- Fashioner efficiency is expanded

- The two-layered outline model is dispensed with, and

- Time and cash are saved by the end of building an actual model

Computer-aided design CAM innovation is the aftereffect of many years of endeavors by various individuals for the sake of creation mechanization. It is the vision of pioneers and innovators, mathematicians, and mechanics, who are attempting to fabricate the future and drive creation with innovation. Many individuals utilize the expression "computer-aided design CAM" when they discuss the product that is utilized to make things with a CNC machine. The computer-aided design represents Computer-Aided Design and CAM represents Computer-Aided Manufacturing, the two of which are utilized to make things. Computer-aided design/CAM programming is utilized to plan and fabricate models, completed items, and creation runs of items.

One more shortening propelled by the omnipresent presence of CAD/CAM in the assembling area is CAS/CAM. This expression represents Computer-Aided Selling/Computer-Aided Marketing programming. On account of CASE as well as CAS/CAM, the center of such advances in the incorporation of work processes and the use of demonstrated rules for a rehashing interaction.

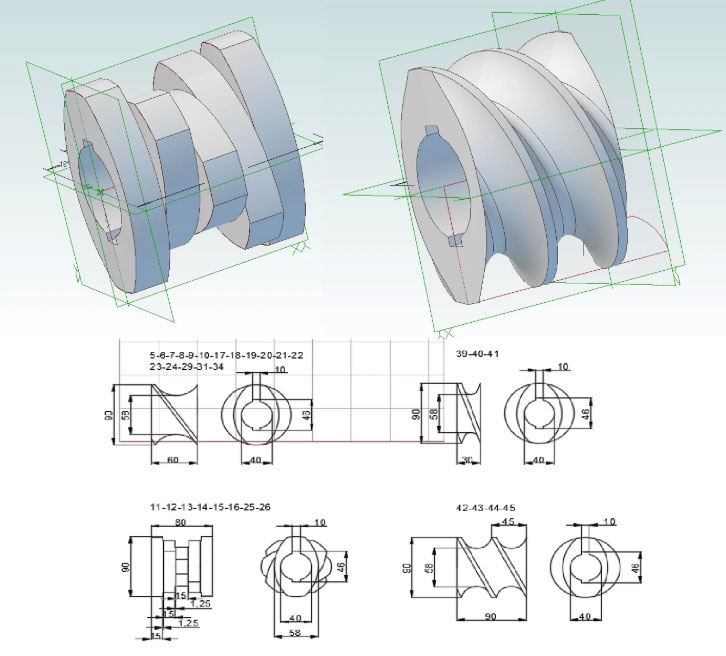

The computer-aided design utilizes a three-layered demonstration which gives many benefits over manual drafting and planning:

CAM can be utilized to computerize a production line through frameworks like constant control and mechanical technology. Since the assembling processes in a CAM framework are PC controlled, a serious level of accuracy can be accomplished that is beyond the realm of possibilities with a human connection point. The CAM framework, for instance, sets the apparatus way and executes accuracy machine activities in view of the imported plan.

Some CAM frameworks get extra computerization by monitoring materials and robotizing the requesting system, as well as some upkeep errands like device substitution. One more benefit of Computer-Aided Manufacturing is that machines can be rapidly reconstructed to work with mass customization: the most common way of making little clusters of items that are specially crafted to suit every specific client. Particulars and drawing changes can be sent rapidly from plan to assembling and starting with one machine then onto the next

The Computer-Aided Design (CAD) model has totally had an impact on the method of Industrial assembling parts and made the plan work more reasonable. There is no question that Computer-Aided Manufacturing (CAM) plan has gone through a critical defining moment since CAD innovation is been utilized. Before CAD, sketchers utilized paper, pencils, rulers, compasses, and manual instruments to approach their drafting. It is many times less useful in the present working environment. The serious issue is that when there are configuration changes, the designer needs to delete and redesign the whole arrangement and that is the reason it is a tedious cycle.