- Quality Assurance

- Quality Control

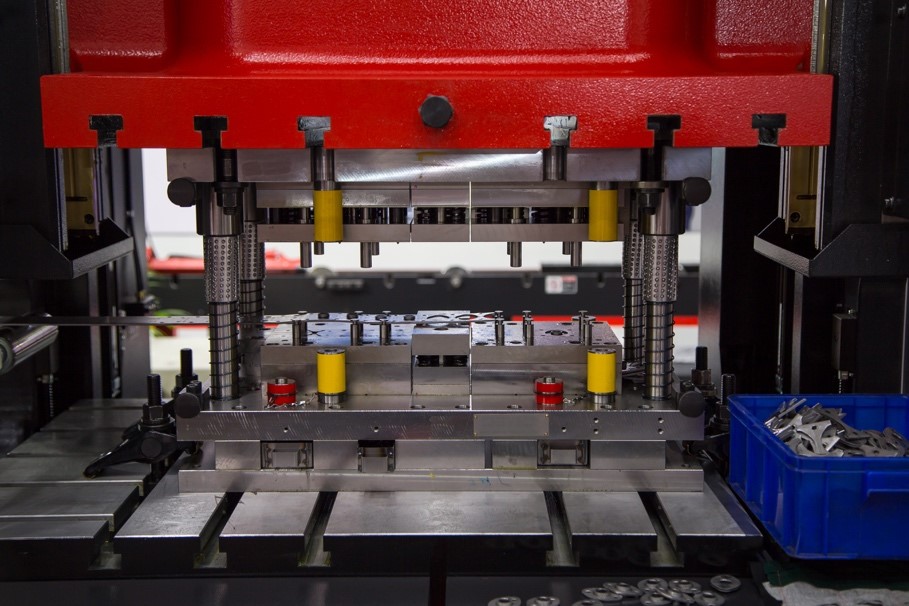

- Factory facility

Quality Assurance

Baiju Enterprises, with its state-of-the-art tool & Die making Arena is in the business for the last 30+ years. Over these years we have gained the loyalties and confidences of the customers by maintaining our quality and standards. We provide the services to the clients according to the guidelines set by ISO. We use modern and ISO certified machinery to deliver the best services to our client in the manufacturing process. We have advanced in-house services like CAD and CNC machines, enabling us to be one of the leading and advanced tool and die-making industries in the market. Our high-quality services and ISO certified standard has made us client’s favourites over the last 30 years.

We provide

Our high-quality services and ISO certified standard has made us client’s favourites over the last 30 years.

Client Satisfaction

When we say our customers are our first and foremost priority, we don’t only say that, we mean it. At Baiju Enterprises, we ensure that the experts inspect every step of the manufacturing process to leave no room for mistakes.

From raw material inspection to quality assurance testing and packaging, we assure that the ISO standards are being fulfilled at every step. So that the services deliver to our clients and customers are always up-to-the-mark.

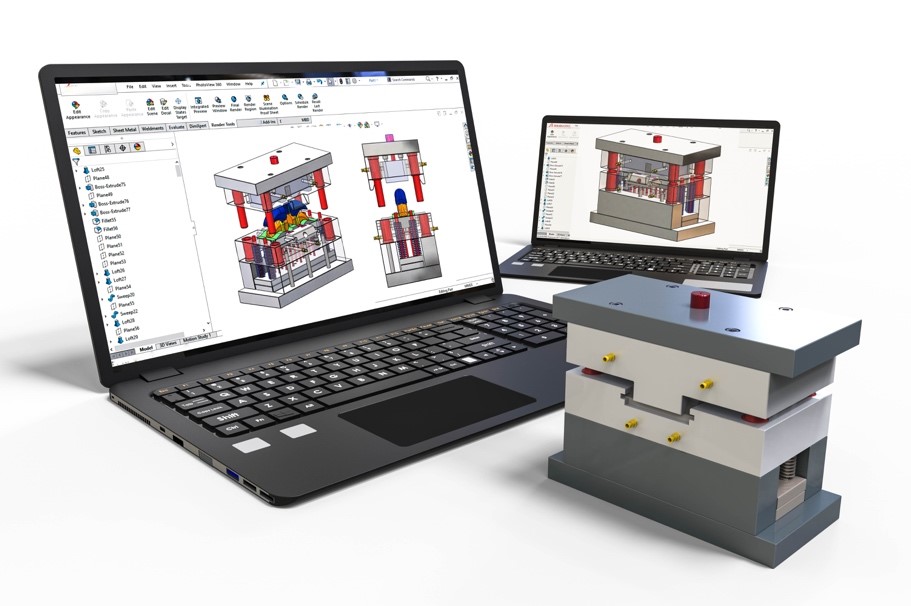

Implementation of CNC & CAD/CAM

CNC Machines along with our CAD/CAM is our biggest asset in providing Quality Tools in the shortrest possible lead times. Increased production speed and increased efficiency.

CAD Designing:

One of the core strucrure of our process is an experienced set of deisgners , with which we have been able to improve productivity.

VMC Machining :

Along with the traditional Milling Machine, the Machinig department have received a boost with the implementation of VMC. These have helped improve our machining time & Precision.

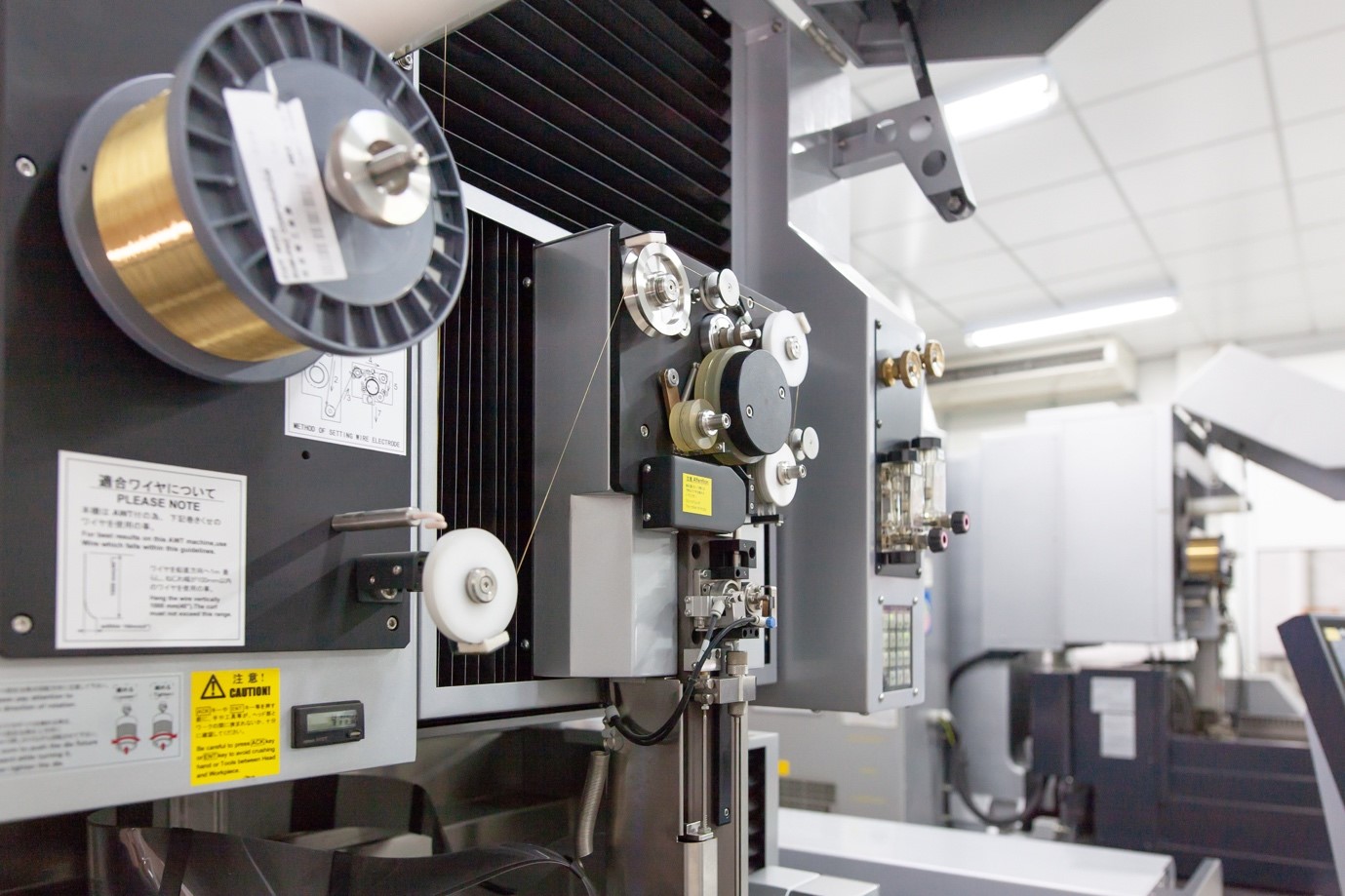

EDM Machines:

Since our requirements and precisions are at Micron levels, the main source of providing accuracy at such levels has been the EDM Department. SODICK & FANUC EDM Machines are one among the many assets of our organization.We have plans to increase the existing productivity and provide cost effective rates by implementing more of such machines.This will ultimately help the clients in having an edge over the competitive market.

These implementation ensures very high levels of precision, cost-efficiency, equipment safety and enables the precision production of parts with Quality.

Quality Process

CAD/CAM Designing:

Designing Of Tool along with Machining & CNC Drgs.

Raw Material Inspection:

Material is inspected for size & dimensions on arrival from Vendors.

Machining – Lathe/Milling:

Rough Machined to suitable dimensions.

VMC Operations:

Machined to suitable dimensions

Bench Work:

Tapping , Filling, Spotting & other works.

Hardness Inspection:

Materials received from hardening subjected to hardness check.

Surface Finishing:

Surface Grinding operations to get desired finish.

EDM Operations:

Materials subjected to wire cutting operations.

Parts Inspections:

Parts are inspected for dimensions & Hardness before Assembly.

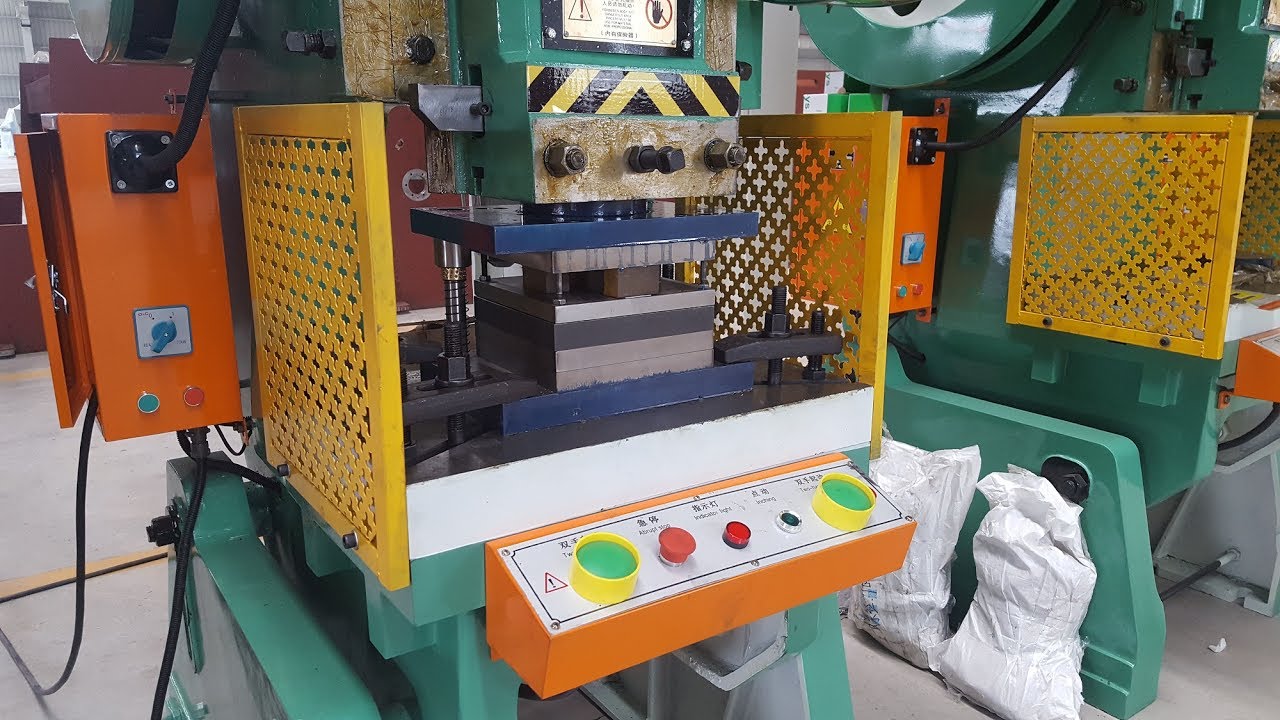

Tool Assembly:

The Checked parts are assembled

Trial & Inspections (CMM):

The assembled Tool is trailed in a Press & CMM is taken on Client's advice.

Packing & Delivery:

The Tool after all inspections is packed and prepared for shipment.