Progressive Tools Manufacturers in Bangalore

A Progressive stamping that bites the dust is an extraordinary, stand-out accuracy apparatus that cuts and structures sheet metal into an ideal shape or profile. bite the dust's cutting and framing areas commonly are produced using extraordinary sorts of hardenable steel called apparatus steel. Passes on likewise can contain cutting and shaping areas produced using carbide or different other hard, wear-safe materials.

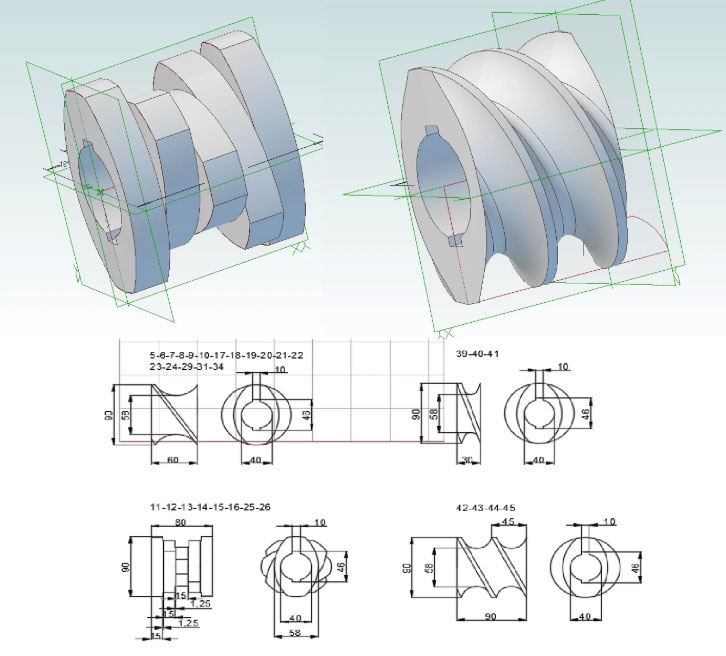

There are numerous sorts of fast stamping passes on stamping, all of which perform two essential tasks cutting, shaping, or both. Physically or mechanically stacked passes on are alluded to as line kicks the bucket. Moderate and move pass on are completely robotized.

Moderate passes on are utilized in higher-volume creation and are intended to work at high paces. Stamping produces top caliber, solid and practical moderate kicks the bucket for the auto, machine, purchaser gadgets, and aviation businesses.

Enterprises, for example, car, protection, aviation, electrical and hardware, and so forth depend vigorously on the large-scale manufacturing made conceivable by the press instrument plan. The accuracy apparatus and kick the bucket are intended to assist makers with aiding in large-scale manufacturing. It requires mastery, experience, and an extraordinary plan group to get everything in precise shape and aspects. Moderate apparatus and kick the bucket are utilized in a few shaping tasks to accomplish wanted plans in a part. We should break down a portion of the significant parts of what helps the assembling business to be the most incredible in moderate instrument and bite the dust shaping. Moderate Tooling is generally utilized by Eigen to create a wide scope of parts and parts. It is a metal stamping activity in which a few methodologies are acted in an ever-evolving press. The interaction includes numerous stages in a decent request to change a metal strip into wanted metal parts. The material is consequently taken care of from a spool into the press and goes on starting with one stamping position then onto the next with each press stroke. Each station along the way does a specific activity at the same time as the bite the dust dives until the part is finished in moderate tooling.